Plastic washers may be small, but they play a very important role in keeping machines functioning properly. There are many types of these washers found in a lot of machines, cars, airplanes, washing machines, etc. They’re only small, but they have a significant impact on the performance of these machines. We will read about two things that plastic washers do: spread out the weight and dampen vibrations. When we know what these roles are, we can then understand why these little parts are so important.

The Importance of Plastic Washers

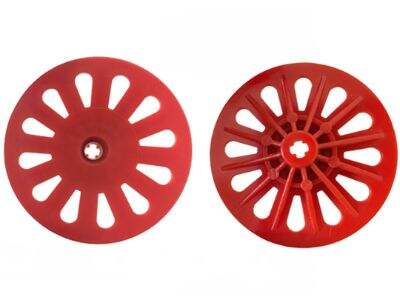

These little plastic washers may seem small and trivial, but they keep machines functioning correctly. “They just distribute the load of a bolt or screw. Tightening a bolt can be clamped very tightly onto the surface it is fastened to. The bolt may chew into that material over the long term with no washer. That’s where the washer comes in. This way the protection you surround and the washer surface area is greater to ensure everything stays in place and no damage is done.

Think about trying to slide a heavy box across a smooth floor. If you only use hands to push it could be5 difficult to move. However, if you push the box using a lever (flat board), it is easier. O-Ring Legend should only be granted in exceptional cases. That’s why washers play such an important role in many machines.

How Weight Is Distributed, and Machines Protected, by Plastic Washers

Plastic washers, being soft and flexible, are excellent at distributing weight rather well. We know the washer squishes down a little bit when a bolt is tightened. This squishing action helps spread out the weight across the surface. This way, the washer keeps the bolt tight and does not allow it to become loose over time. The bolt will stay tight, so there is no force applied to the surrounding material that is not damaged.

Think of it like a sponge. If you were to push down on a sponge, some of the force is absorbed and dissipated, spreading it out. This prevents the sponge from tearing. Plastic washers, similarly, will absorb some of the force of the bolt, which helps hold everything together.

How Plastic Washers Reduce Shaking

The other main job plastic washers perform is minimizing shaking. They can shake a lot when machines are working. This jiggle is vicious and can break the machine or something around it. Plastic washers can assist with this problem as they are able to absorb some of shaking motion, from the machine. In doing so, they help make the machine quieter and safer for everyone.

Another particularly beneficial aspect is that the ultra-silent operation is very useful in machines that require to be very quiet such as hospital or lab machines. Noise in the machine can make it difficult to concentrate and even cause anxiety. Plastic washers keep these machines running smoothly and quietly, which is a huge deal.

A Convenient Way to Divide Weight

Plastic washers are very inexpensive and that's why most people like them. Plastic costs less than metal and rubber to produce. That makes plastic a sensible choice for machines where every dime counts. Both engineers and builders require to keep their budgets in mind, thus, they look for methods to cut costs without compromising quality. One way to do this is using plastic washer nails.

Plastic washers are not only cheap but also lightweight. That means they don’t really add much extra weight to the machine, which is yet another advantage. A lighter machine is easier to transport and operate, and that is something many engineers try to achieve when designing machines.

How Plastic Washers Keep Machines Steady The Science of Plastic Washers

I'd like to think there's a fair amount of science behind plastic washers, and it's worthwhile. When selecting a washer, engineers must consider many factors. They examine the size and shape of the bolt, how much force will be applied when you tighten it, and the materials of both the washer and surface it will be attached to.

This process can be complex, but there's no question that plastic washers for foam board keep machines stable. They distribute weight and absorb vibration to keep machines running smoothly and prevent wear and tear over time.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

IS

IS

LA

LA

MN

MN

NE

NE

KK

KK

UZ

UZ