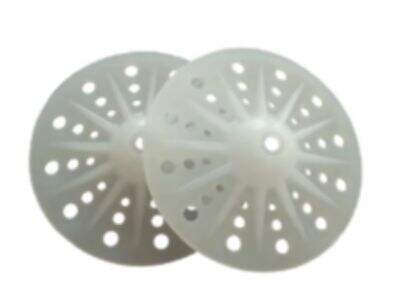

Hi everyone! We are not going to talk about anything that seems small, but is actually an incredibly big deal: Plastic washers! These small items serve a wide variety of applications, and we learn about how plastic washers can be deployed in hot environments, and how to use them safely.

What Are ‘High-Temperature Environments’?

First, what do we mean by “high-temperature environments”? Hot places, as in really hot places! For instance, consider the interior of your oven while you are baking cookies. It gets very hot in there! The same thing can be said about a car engine. Just like a vehicle in motion, its engine also gets very hot when running.

But in hot areas, plastic washers are quite beneficial. They are used in a wide variety of machines and tools. But we have to be careful, because heat can alter plastic. Plastic can melt or warp when it becomes too hot. That can prevent the washer from working properly. Washers assist as well in forming a tight seal between two things and preventing them from rubbing too much against each other. When a insulation washers breaks down, it creates issues.

How to choose plastic washers for hot places?

So, how do you select the proper plastic washer for hot service? Below are some key tips to be mindful of:

Material: Various plastics can withstand different temperatures. Some plastics are stronger and can withstand heat, while others may not fare well under heat. Be sure to use a washer made of a type of plastic that can handle the heat will be exposed.

Size: A washer that’s too small won’t get the job done, but one that’s too big may not fit where you need it to. This is why it is so important to know exactly what size washer you need before you start looking for one.

How to Make the Most of Washers: These two kinds of washers are made for different purposes. Certain washers are better suited for high heat conditions, whereas others may be designed for special environments with chemicals or moisture. Be sure to select a insulation washers plastic that is made for the task you need to perform.

THE SIGNIFICANCE OF TESTING PLASTIC WASHERS

Even if you select a washer designed to withstand high temperatures, it’s still a good idea to do a test run before using it on anything important. Why is this important? Because different jobs can generate varying amounts of heat. You’d need to ensure your washers can truly handle what you’re asking it to.” Testing will allow you to catch any issue before it could occur.

Plastic Washers: Why So Hot, How to Install and Maintain

After selecting the proper washer and testing it, it is the paramount concern that it should be rightly installed and well-maintained over time. Some helpful tips for doing so would be:

Ensure the washer is in its place and centric. Not too tight, but not so loose that it leaves a gap.

Never overtighten screws or bolts as this can harm the washer and cause failure. Finding the right balance when tightening matters.

Inspect for wear and tear regularly. Check for things like bending, cracking or discoloration. If you read any of these problems, it is the time to change the washer and buy a new one.

Pros and Cons of Using Plastic Washers in Hot Locations

Image balance of advantages and disadvantages 6Finally, let’s look at the pros and cons of plastic washers in hot circumstances.

Plastic washers can be very lightweight, which can be a boon for usability. They are tough and long-lasting as well. They are also typically cheaper to manufacture than metal washers. Due to the moisture, plastic washers can be helpful where the metal washers start getting rusted or corroded by other chemicals.

BAD: But there are limits to the heat resistance of most plastics. On truly extreme heat-trip situations, you could be looking at a completely different type of washer. Moreover, plastic washers can be worn out sooner than the metal ones after a long-term use, therefore you have to check them regularly and replace them whenever required.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

IS

IS

LA

LA

MN

MN

NE

NE

KK

KK

UZ

UZ